Q: We have a large heat exchanger under feedback control. When the load changes, we experience a temporary but substantial error in the controlled outlet temperature. The heating medium is steam. I’m told that feedforward control could reduce the upset in the outlet temperature. How should we configure a feedforward loop? What options do we have in configuring it? I’d appreciate your advice.

Z. Friedmann

control engineer

A1: When controlling the outlet temperature of a heat exchanger by feedback control you should realize that, even if the PID loop is tuned correctly, corrective action can only start when an error has already developed. In contrast, feedforward control can anticipate the error that’s likely to occur as soon as the load (incoming process fluid flow or temperature) starts to change. If correctly "modeled," it can cancel or reduce the upset the load change would otherwise cause in the outlet temperature.

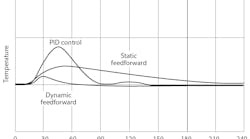

While feedforward models can be steady state, changes in the system dynamics or errors in temperature measurement or the control models upon an upset will still cause the loops to allow some error to occur. If you want to minimize this error, you should add cascade trimming to the feedforward model to provide dynamic compensation. In general, static feedforward control can cut the PID error by approximately half, while dynamic feedforward loops reduce the error to about 10% of the feedback error (Figure 1).

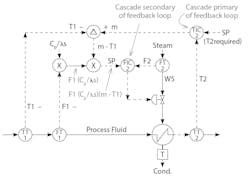

The heat balance of a steam heated heat exchanger can be stated as below:

F1Cp(T2-T1) = Wsλs

where:

F1 = flow of the incoming process fluid

Cp = heat capacity of the process fluid

T2 = controlled outlet temperature of the process fluid

T1 = incoming temperature of the process fluid

Ws = heating media (steam) flow

λs = latent heat given up by the condensing steam

Solving the equation for steam flow (Ws), the required steam flow Ws is:

Ws = W (Cp/ λs) (T2 - T1)

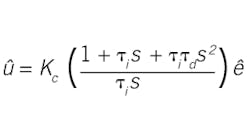

The feedback controller (TIC -2) should have an integral to eliminate any steady-state offset error that could be caused by sensors, model or the calculation errors, so it will respond only to the changes in the heat capacity ratio. Also, the dynamic compensator should be tuned with the feedback controller in manual, so the integrated error will be zero before feedback is added.

Feedforward control is usually used only by experienced control engineers when the process is sensitive to disturbances and slow to respond to corrective action when controlled by feedback control or when the product is of high value. The hardware cost is similar to the costs of feedback cascade control, but the need for good understanding of the process is higher.

Béla Lipták

A2: The article “Process control journey: process control concepts and practice,” can be found at https://resourcium.org/journey/process-control-concepts-and-practice. This tutorial may be helpful to answering your question about how to apply feedforward control.

Russell Rhinehart

emeritus professor,

Oklahoma State University

A3: [Editor’s note: the comments below were made previously by the late F. Greg Shinskey.]

Incremental feedforward is an impulse function that‘s applied to the manipulated variable only on a change in the load variable—it has no steady-state component. To minimize integrated error following a load change, the feedforward signal must be positionally applied in the steady state. This can be done either by additive with a fixed gain, as is typical when controlling liquid level, or by multiplicative, where the gain of the multiplier is set by the output of the feedback controller, which is often used when controlling temperature and composition.

Avoid incremental algorithms at all costs—they float and will cause all kinds of trouble and confusion.

Q: [Editor’s note: multiple versions of the following question were submitted and are summarized below.]

How can automation and control professionals contribute to the success of the SpaceX project, which is planning roundtrips to outer space via reusable rockets that would land on the Moon by 2025 and on Mars by 2028? On April 18, a launch was cancelled due to pressurization problems. It was briefly successful on April 20, though a minute after liftoff, the rocket started to tumble and had to be destroyed.

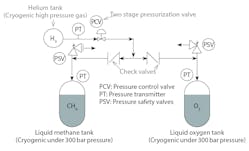

On April 18, this charge valve (PCV) froze, and the test had to be canceled. If an automation and control engineer was designing the system, this freezing potential would probably have been realized and the PCV would have been heated before ignition, or absolutely dry helium would have been used, so there would have been nothing to freeze.

As to the rocket's tumbling, followed by its destruction on April 20, an automation and control engineer would have warned that successfully igniting 33 engines at exactly the same time is rather unlikely and therefore balancing controls are needed. One option is to balance the rocket by making the lifting force of some of the engines adjustable (variable fuel flow) and throttle them to compensate for force that’s lost due to the failure of some engine(s). This balancing algorithm should have the feedforward format, so that tumbling is anticipated and corrected for before it starts.

An automation and control engineer might also question the choice of using methane fuel because the space industry has more experience with hydrogen. Also, a kilogram of hydrogen has three times the mass energy of methane and it’s lighter. Another argument in favor of hydrogen is that it is easier to make on Mars for the return flight than is methane because solar energy can be used to split the ice on Mars into hydrogen and oxygen to fuel the return flight.

Béla Lipták