A Journey Toward Autonomous Operations

Already automated, the process industries are poised for their next advance: industrial autonomy. Autonomy goes beyond automation by adding layers of smart sensing and machine cognition to anticipate and respond to unforeseen circumstances, ultimately removing the need for human intervention. In a fully autonomous operation, the system is responsible for all aspects of the operation–from startup through safe shutdown. This Knowledge Center is devoted to the technical advances and workflow best practices required for industry to take its first steps on that journey. Our Sponsor, Yokogawa is supporting customers on their journey with a pathway named Industrial Automation to Industrial Autonomy (IA2IA). See the many resources below.

Special Features

Special Features

Whitepaper:

Reinforcement-learning AI marks significant advances in Industrial Autonomy

Reinforcement-learning AI marks significant advances in Industrial Autonomy

AI algorithm based on Factorial Kernel Dynamic Policy Programming (FKDPP) joins PID and Advanced Process Control (APC) to deliver new levels of autonomous operations.

Podcast:

Industry accelerates its journey to Industrial Autonomy

Industry accelerates its journey to Industrial Autonomy

To provide a status report on our collective journey from Industrial Automation to Industrial Autonomy (IA2IA), Keith Larson is joined by Yokogawa's Tom Fiske.

Article:

Industry accelerates its journey to Industrial Autonomy

Industry accelerates its journey to Industrial Autonomy

The global pandemic has increased the sense of urgency to implement digital transformation strategies at scale, including those advancing the realization of Industrial Autonomy. Control Magazine editor interviews Yokogawa's Dr. Tsuyoshi Abe to find out how they are addressing this acceleration.

Resources:

Resources:

Whitepapers:

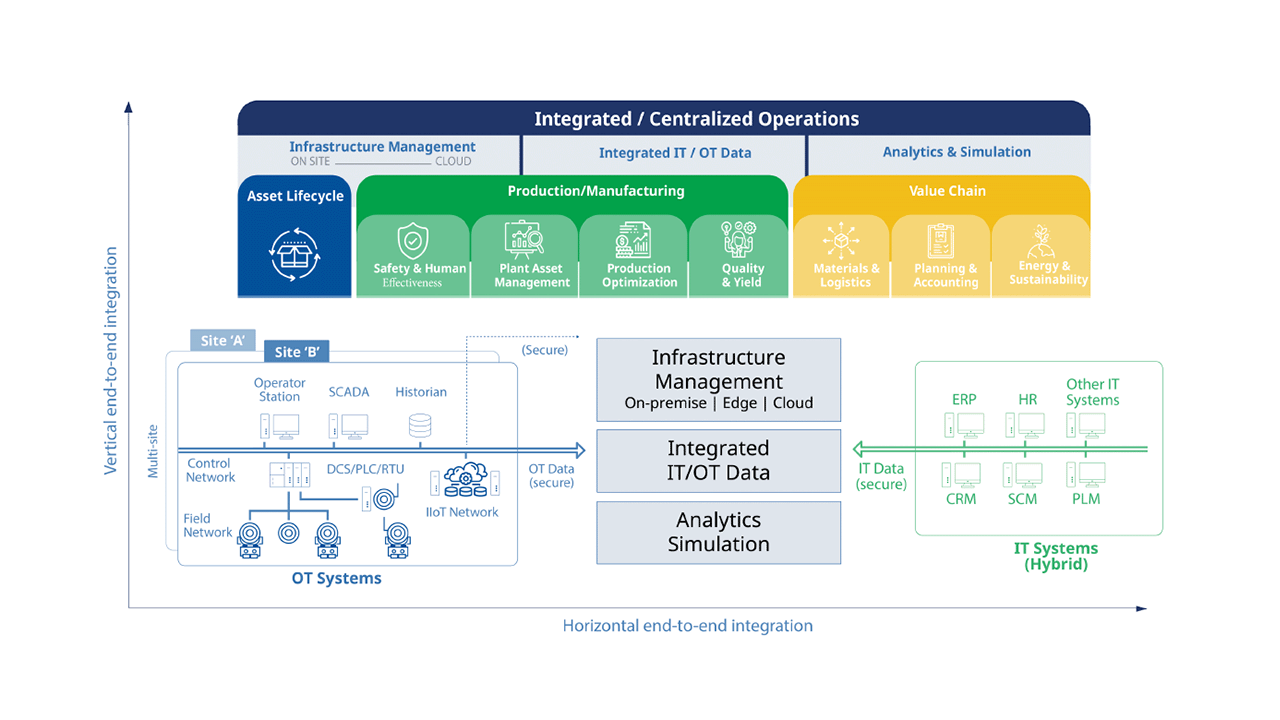

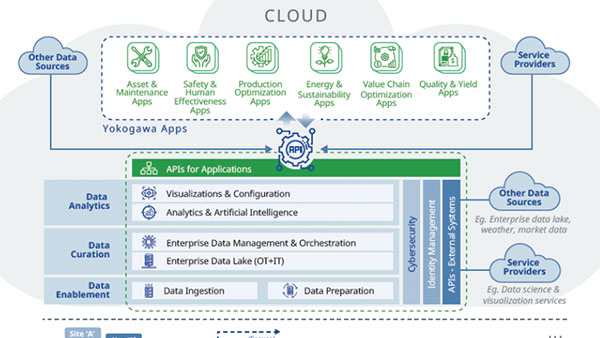

Industrial Autonomy: The Pathway to Autonomous Operations

Industrial Autonomy: The Pathway to Autonomous Operations

The journey of industrial automation to industrial autonomy (IA2IA) passes through increasingly intelligent operations enabled by digital technologies and horizontally and vertically integrated systems.

The Three Top Use Cases for Process Artificial Intelligence

The Three Top Use Cases for Process Artificial Intelligence

How real-time artificial intelligence and machine learning can improve plant performance and enable increasingly autonomous operations.

Why a Robot is Your Next Productivity Tool

Why a Robot is Your Next Productivity Tool

Increasingly autonomous and cost-effective, today’s drones and robots can help keep human operators safe as well as perform previously impractical tasks.

Research:

The Acceleration of Industrial Autonomy and Its Impact on Sustainable Manufacturing

The Acceleration of Industrial Autonomy and Its Impact on Sustainable Manufacturing

The global survey reveals that the number of manufacturers moving forward with industrial autonomy is clearly increasing, and that there is a high awareness of the expected benefits on environmental sustainability.

The Outlook for the Shift to Industrial Autonomy

The Outlook for the Shift to Industrial Autonomy

In From robots and quantum computing to digital twins and AI, new technologies are revolutionizing the way that plants operate. They are facilitating a shift whereby physical tasks and decision-making processes are being made more autonomous with the aim of improving productivity and worker safety. In today’s business environment, operational resilience has never been more important.

Podcast:

Industry Perspective: The Road to Autonomous Operations: Control Magazine Q&A with Yokogawa

Industry Perspective: The Road to Autonomous Operations: Control Magazine Q&A with Yokogawa

Control magazine editor in chief Keith Larson and Dr. Tsuyoshi Abe, senior vice president and head of the Marketing Headquarters at Yokogawa, talk about the ongoing transition that is underway—from industrial automation to industrial autonomy, and what that means for the future of the process industries.

Article:

The Road to Autonomous Operations: Control Magazine Q&A with Yokogawa

The Road to Autonomous Operations: Control Magazine Q&A with Yokogawa

The automation of the process industries has come a long way in a relatively short time. A hundred years ago, the human operator was the primary process controller, relying on rudimentary local indicators plus his own senses to know when to tweak a valve here or there to keep the process in line. Pneumatic controllers were in their infancy, and loop-tuning more art than science.

Video:

The Evolution of Industrial Automation

The Evolution of Industrial Automation

What do steam, electricity, automation, and digital technology have in common? These have been driving the industrial revolutions that transformed our modern society. With each of these advancements—the steam engine, electricity, automation, and digital technology—the world around us evolved. And, it’s happening again. But this time, the revolution is powered by the cloud, AR/VR, the Internet of things (IoT), robots and drones, and artificial intelligence (AI), along with increasing computing power and data.

Industrial Automation to Industrial Autonomy

Industrial Automation to Industrial Autonomy

Yokogawa considers industrial autonomy to be when plant assets and operations have learning and adaptive capabilities that allow response with minimal human interaction, empowering operators to perform higher-level optimization tasks. Yokogawa co-innovates with our customers to accelerate the “IA2IA” Journey.

Related Links:

Sustainability accelerating autonomy investments

Sustainability accelerating autonomy investments

It’s been but a few years since Yokogawa first described the shift by which physical tasks and decision-making processes across the process industries are being made more autonomous through digital technologies. They tagged that journey as the path from Industrial Automation to Industrial Autonomy (IA2IA), and paired it most closely with potential improvements in productivity and worker safety.

Industrial Autonomy: The Dawn of a New Era in the Process Industries

Industrial Autonomy: The Dawn of a New Era in the Process Industries

Process manufacturers must achieve stable and profitable operations in the face of a business environment characterized by a high degree of volatility, uncertainty, complexity and ambiguity. To meet these challenges, companies are embracing a plethora of established and emerging digital technologies to significantly transform operations, control costs, reduce downtime and improve profits.

Digital Twin: The Journey Toward Autonomous Operations

Digital Twin: The Journey Toward Autonomous Operations

A digital twin is a digital representation of a human, device, system, or process, mirroring the actual process and with full knowledge of its historical performance. By simulating devices, systems, or processes to predict future performance, digital twins drive agility and convergence of understanding to enable effective decision-making and determine strategies to maximize safety, reliability, and profitability.

"Yokogawa Technical Report" is a technical journal which includes articles about technologies and product information developed by Yokogawa.