Greg: In this month’s column, I have a conversation with myself while also taking on the role of being a mentor. In part 1, I focus on the challenges faced in the past that are still present and possibly more problematic today. To better understand the failures and successes in process control applications and the possible sweet spots for artificial intelligence, here are the many challenges in the process industry often not recognized.

Mentor: Processes are nonlinear with dead times, time constants, and gains that change with production rate and operating conditions of the process, as well as the design and installation of the instrumentation. Process dynamics can often change by factor of four or more when changes in production rate, operating conditions, startup, and hidden factors come into play.

In addition, pH control with a strong acid or strong base can exhibit one or more orders of magnitude changes in process gains that are highly dependent upon operating point. Temperature sensor and electrode lags are greatly affected by velocity and fouling. Changes in pH electrode dynamics can be extraordinary due to aging or fouling of the measurement electrode increasing the measurement lag by orders of magnitude.

Control valve resolution and sensitivity limits and lost motion often seen in rotary valves designed for tighter shutoff and higher capacity add significant dead time and a loss in precision that also result in limit cycles. The stroking time is a serious limitation for fast control, particularly in compressor and pressure control applications. Improper installation of sensors either from the start or during maintenance can aggravate the problems (looser fit of sensor in a thermowell creating an air gap), as well as promote mishandling and dehydration of glass electrode (deterioration of fragile thin gel layer increasing error and lag by orders of magnitude, equilibration of the reference electrode taking hours to days). The effect of signal filter times and execution intervals often not recognized in terms of increasing loop dead time and hiding the true variation in the process, being particularly detrimental to fast loops.

Greg: What is the general availability of process control algorithms needed?

Mentor: Key capabilities in PID and MPC are not widely available. Most DCS and PLC do not have the MPC built in as an option to provide for fast execution. Consequently, software must be purchased and interfaced with execution times much slower (e.g., 1 minute rather than 1 second).

Often alternative PID structures and setpoint lead-lags are not offered, reducing the flexibility for improving setpoint response, batch control, and optimization. Different PID forms are used with inconsistent names and different tuning units and interactions. Conversion of tuning settings between different forms is not widely available.

The ISA Mentor Q&A post, “How Do You Convert Tuning Settings of an Independent PID?” (isa.org) addresses this issue. Surprising and disappointing is the loss of external-reset feedback capability in most PID in the evolution of pneumatic controllers into analog and digital controllers. Some PLCs do not offer the standard PID form and a few even more disruptively use engineering units often seen in academic literature instead of percent of controlled variable and percent of manipulated variable in their algorithms. The fact that the PID algorithm fortunately works with percent input and output signals in nearly all industrial PID is not commonly recognized. Just imagine the PID gain setting for a flow controller with a scale of 0 to 200,000 kph.

Mentor: Methods that propose to identify the process dynamics from closed-loop operation are inherently flawed due the effects of control algorithm design and implementation. Control loop variability is transferred from the controlled variable to the manipulated variable by PID and Model Predictive Control (MPC). The tighter the control, the more the disturbances are seen in the manipulated variables. Many controllers interact with each other requiring decoupling or detuning in PID and multivariable MPC models. Some controlled variables are interrelated. The PID and MPC tuning affects what is seen in the response of the controlled and manipulated variables and can thus change as part of a scheduled or spontaneous adjustment of tuning settings. For this and many other reasons, open-loop tests are done to identify the dynamics for PID and MPC applications. To make AI seem faster, easier and less intrusive, a design of experiments (DOE) is not commonly used in AI development.

Greg: What are some of the additional challenges in process dynamics?

Mentor: Besides processes having complex dynamics, including inverse response, there are also many processes with an integrating response (level, gas pressure, batch pH) and a few with runaway responses due to positive feedback (highly exothermic reactors). A common misconception is that a slow process response is detrimental. If the slowness is due to a large process time constant, disturbances are attenuated, and the controller gain can be greatly increased.

In runaway processes, it is critical that the positive feedback time constant is large so that controller can catch up with the acceleration in temperature and prevent a point of no return. The kinetics of some chemical processes and nearly all biological processes have multiplicative factors where a low concentration can cause a poor production rate even though the temperature or pH is right and vice versa. The multiplicative factors for biological processes are extensive.

Greg: It has been proven that the PID is the best control algorithm for dealing with process input disturbances whereas the academic literature commonly shows process output disturbances. What is the reality?

Mentor: Measured and unmeasured changes in process inputs most notably in a stream composition, flow, pressure, temperature and physical properties are prevalent in the process industry. There are also changes in equipment conditions that affect mass transfer and energy transfer, reaction rates and changes in phase, such as fouling of surfaces and deactivation of catalyst. These changes are classified as load disturbances.

The stream conditions shown on a process flow diagram are rarely constant or exactly match what is happening in the process. Load disturbances can be extended to include any change in process parameters for the material and energy balances. Every PID controller can deal with these differences, otherwise automatic control would not be necessary and simply setting the PID controller at a fixed manual output for a given production rate would be sufficient. The streams may or may not be entering the process at exactly the same point as the manipulated variable. Also, the effect may be seen in terms of changes in utility streams, for example utility temperature, and environmental conditions such as ambient conditions, particularly cold rain storms’ effects on distillation column internal reflux, that are often seen in- changes in heating and cooling of process equipment or piping. The load changes may affect the controlled variable much faster and sooner than the manipulated variable, but load changes still work through the material and energy balances in the process that determine the controlled variable.

Greg: What about signal filtering?

Mentor: The filter time must generally not be larger than 20% of the total loop dead time and reset time to prevent an appreciable deterioration PID performance ultimate and practical limit, respectively. Most do not realize that a filter time larger than the process time constant can make trend recordings look better due to attenuation of what is really happening.

I was at a conference where the presenter said his company almost did not let him do his presentation because it wanted to keep the knowledge proprietary. The presenter had enormously increased the signal filter time which enabled him to have a an incredibly smooth response to a disturbance seen in the trend recording of the filtered signal. He did not realize and show the reality that the unfiltered controlled variable error was horrendous.

Greg: What is the most common mistake in tuning?

Mentor: People tend to use too much integral action because it behaves the way they would in not proactively reversing the direction of the manipulated variable until the error changes sign to deal with the inevitable dead time in the loop response. If there is an oscillation, people tend to think the cause is too much gain action. If the oscillation period in the process variable is more than 10 times the dead time, the cause is most likely excessive integral action. If the period is between 10 and 30 times the dead time, the cause is most likely stiction and the amplitude can be decreased by increasing the PID gain. If the period is approaching or exceeding 40 times the dead time in a lag dominant, integrating, or runaway process, the cause is most likely the product of the PID gain and reset time being too small most often caused by an integral time too small but in some cases a PID gain too small.

There is effectively a window of allowable gains that can pose severe safety issues for processes with positive feedback. If the PID gain is too small, the controlled variable in a runaway process can accelerate to a point of no return causing a shutdown and relief devices to blow endangering equipment and people.

Greg: What is the most common mistake in feedforward control?

Mentor: The literature tends to show a feedforward multiplier. A feedforward multiplier is reserved for dead time dominant processes. Other processes have a change in process time constant that counteracts the change in dead time with a feed flow change. A feedforward summer is easier to implement and more in tune with the process.

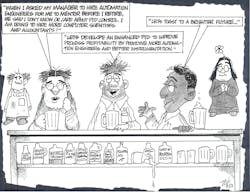

Greg: A big personal concern is the loss of recognition of the value of PID control and the loss of expertise. Management is increasingly focused on budgets and schedules with a business instead of an engineering background. The tendency to lean toward copy jobs results in a loss of practical control experience which is underestimated in terms of its long-term impact. Users tend to not have as much time or inclination to read articles and books on process instrumentation and control.

The chemical and especially the biological production companies do not encourage and may even prohibit the publication of learning experiences from successful applications. Unfortunately gone are Greg Shinskey, the world’s greatest PID expert, and Peter Harriott, professor Emeritus at Cornell University, who is the author of the book “Process Control” that alerted me to an equation for PID peak error and issues in heat exchanger control.

Most of the experts I know are in their 70s or approaching their 70s. This includes the academics who wrote great books on the practical applications of PID control, such as Karl J. Astrom, Thomas F. Edgar, William L. Luyben, Duncan A. Mellichamp, James B. Riggs and Dale E. Seborg. The result is the capability of the PID is increasingly underutilized. My creation and leadership of the committee that recently completed and got approved the ISA-TR5.9 PID Algorithms and Performance Technical Report is an attempt to turn this around.