Once designed and installed correctly, maintaining temperature measurement accuracy and operational integrity over the long haul becomes the focus. Proper maintenance of a temperature measurement point can help reduce the risk of measurement failure as well as ensure ongoing accuracy. High-quality resistance temperature detectors (RTDs) can be extremely stable, but thermocouples can begin drifting as soon as they are put into operation. All temperature sensors, even high-quality ones, can degrade over time due to harsh process and environmental conditions.

Sensor degradation can lead to an abnormal measurement condition called on-scale failure. This is the indication of a valid measurement value that appears to be within process alarm limits, when the data is, in fact, inaccurate. If personnel cannot identify atypical temperature behavior such as on-scale failure, they might be unaware of problems occurring within the process. This lack of awareness can lead to unnecessary process shutdowns and safety issues, as well as negatively impact process efficiency and quality.

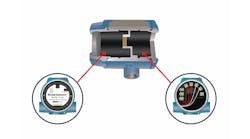

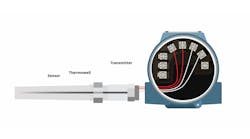

Diagnostic innovations have advanced the continuous maintenance capabilities for process instrumentation and sensor health monitoring, giving users confidence in both instrument performance and measurement accuracy. Emerson’s Rosemount™ Temperature Transmitters feature advanced diagnostic capabilities that help proactively identify issues before they impact productivity and provide information to the right people at the right time, resulting in faster decision making.

Ensuring measurement accuracy

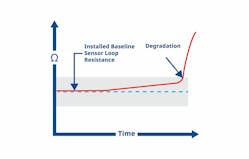

The Thermocouple Degradation Diagnostic monitors the resistance in a thermocouple sensor loop. This diagnostic notifies operators of an increase in sensor loop resistance, which can indicate that the sensor is deviating from the true temperature value and potentially failing.

It lets users set a resistance limit for each unique installation. For example, if a plant’s standard installation is running at 30 ohms, the transmitter can be set to alert technicians if it hits a threshold of twice the baseline, or in this case, 60 ohms. Once it hits the threshold, the transmitter will keep the process operating but send an alert.

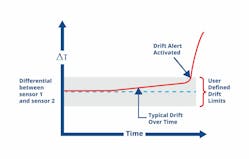

Another diagnostic available in Rosemount Temperature Transmitters is Measurement Validation. It works by evaluating sensor noise. Before a sensor fails, it will exhibit signs of degradation such as increased signal noise, which will often result in inaccurate but transient on-scale readings. Measurement Validation monitors the signal noise and uses it to calculate a deviation value, indicating the magnitude of the noise, which is compared to a user-selected alert limit. If this limit is exceeded, the user is notified, allowing action to be taken.

Measurement Validation can detect increases in signal noise due to loose or corroded connections, high vibration levels or electronic interference. In addition to detecting on-scale failures as a result of these conditions, Measurement Validation also performs a rate of change calculation to differentiate abnormally fast temperature changes due to sensor failure from actual temperature swings.

Solving sensor drift

Sensors are sometimes prone to drift, especially when exposed to extreme process conditions. Sensor drift is a common issue found in the chemical, refining and power industries and in applications such as coker heaters, crude vacuum distillation units, furnaces and hydrocrackers. Drift can have a significant impact on the accuracy and reliability of sensor data. Gradual, subtle changes in the sensor happen over time, causing discrepancies between the true process temperature and the output of the sensor.

Reducing recalibration tasks

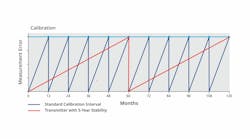

Another important component of maintenance of a temperature measurement point is calibration frequency. When using Rosemount Temperature Transmitters, it is possible to calculate the frequency needed for calibration, as the stability specification plays a large role in how often they must be recalibrated.

For example, the Rosemount 3144P Temperature Transmitter has a five-year stability specification. Users should take into account a transmitter’s stability and accuracy specifications in conjunction with their own onsite requirements to calculate how often units should be inspected. This approach can often extend the calibration interval, freeing maintenance personnel to do other important tasks.

Maintaining accurate instrumentation is a vital element in the productivity of a process. Temperature sensors will degrade over time, and the inability to monitor this behavior can lead to false alarms, lower product quality, energy inefficiencies or process shutdown. Emerson’s Rosemount Temperature Measurement Solutions are designed to help maintain accurate instrumentation and keep your process up and running over the long term. Advanced diagnostic capabilities also help users do more with less by enhancing overall operations, augmenting the capabilities of their front-line teams, and empowering them to direct their efforts towards the highest value-added tasks.

As people around the world demand a more sustainable way of life, process industries need innovative solutions that are proven safe, reliable, and efficient. Emerson’s Rosemount Temperature Measurement Solutions are designed to tackle the most challenging process design, installation, operation and maintenance challenges to ensure industry can meet its safety and sustainability goals.

In addition, the MyEmerson portal serves as go-to source for the necessary service, education and training to make this vision a reality.