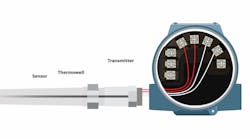

When it comes to accurately measuring the temperature of the flow inside a pipe, the thermowell has long played an essential role. It brings the sensor into close, conductive proximity with the process fluid while also protecting the sensor from often harsh conditions. But the thermowell also comes with several installation challenges.

First, installation of a thermowell into a pipe requires a shutdown of the process, directly affecting productivity. Pipe modifications, such as welding or cutting, are required to install a thermowell, and classified environments may need to be fully cleared of explosive hazards for the work to be performed.

In addition, small line sizes present a challenge. Stem conduction of ambient heat sources can impact measurement accuracy when the immersion depth is less than 10 times the thermowell tip diameter. It is often impossible to achieve this immersion depth in small line sizes without significant modifications to the pipe, such as adding a tee.

Finally, installation of a temperature measurement solution becomes more challenging when components are sourced from multiple vendors and made to fit properly. Assembling components from multiple vendors complicates and lengthens the overall installation process.

Temperature measurement without a thermowell

Rosemount X-well Technology is available with either the Rosemount 3144P Wired Temperature Transmitter or the Rosemount 648 Wireless Temperature Transmitter. Using the wireless transmitter option provides additional benefits of not having to run new wires to the device for power and communications. As a result, wireless instruments are routinely commissioned in less than an hour, leading to an even greater reduction in overall installation time.

Rosemount X-well Technology uses a built-in algorithm to extrapolate the internal process temperature based on surface temperature, plus the conductive properties of the pipe (composition and thickness). This delivers temperature measurement accuracy in line with that of a sensor in a traditional thermowell. Plus, Rosemount X-well does not encounter the issues that often make thermowells inaccurate for line sizes smaller than 5 inches.

Rosemount X-well Technology is also suitable for any applications that have high-velocity, abrasive material within the process or corrosive processes that dictate an exotic material for the thermowell. It also makes sense for any application where a traditional thermowell path is too costly or too complicated.

One European chemical maker recently utilized Rosemount X-well Technology with Rosemount 648 Wireless Temperature Transmitters to further simplify the installation of 65 temperature measurement points to determine flowrates via energy balances for a heat exchanger that was particularly sensitive to erosion. The solution was commissioned in under an hour and seamlessly connected to the existing wireless infrastructure without process shutdown or production loss.

Universal Pipe Mount’s cut-to-fit banding design brings new functionality to this technology. Standardized units can be stocked in inventory, installed, moved, and reinstalled on pipes of different line sizes. This provides value to operators, as they can rapidly deployment measurement solutions from their standardized inventory in emergency situations. They can also use a single device to validate several existing insertion measurement points over time.

Overall, for those looking to avoid installation and other thermowell challenges, but want to obtain accurate process temperature measurements, Rosemount X-well Technology is your go-to solution.

Three components in one integrated solution

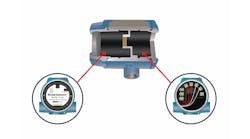

For those applications where a thermowell still makes sense, another Emerson approach that significantly streamlines installation time and effort are fully integrated solutions that include sensor, transmitter and thermowell already fully assembled and ready to install.

This approach offers advantages from a procurement standpoint, eliminating the need for multiple quotes and purchase orders. In addition, it avoids the management of multiple shipments and lead times from separate vendors. Plus, different sources of each of those components can require time-consuming workarounds to accommodate unanticipated incompatibilities.

Sizing the thermowell and the sensor together is more complicated if you purchase them from different sources. It can increase the risk of a misfit—either the sensor’s too long and it won’t fit in the thermowell, or the sensor’s too short, which could lead to measurement inaccuracies if the tip of the sensor is not making contact with the inner wall of the thermowell.

Meanwhile, each temperature transmitter must be configured to match the sensor type that’s being wired. If the user buys them pre-assembled from the same vendor, this extra step is eliminated. Separate sourcing also creates extra work when it comes to wiring in the field. Separately purchased transmitters require the sensor to be physically wired to the terminal block.

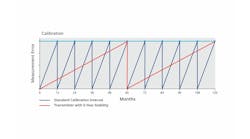

Users can achieve a higher level of performance when the transmitter and sensor are ordered together by specifying Callendar-Van Dusen (CVD) constants. These are coefficients that characterize how a specific resistance temperature detector (RTD) operates at different temperatures. Sourcing components together makes it easier to achieve transmitter-sensor matching because Emerson can preconfigure the transmitter with CVD constants for that specific RTD at the factory. There’s no manual entry of the constants into the transmitter as would be required to pair an RTD from one company with a transmitter from another.

Emerson’s complete point solutions and Rosemount X-well Technology give process industry users streamlined and non-intrusive temperature measurement solutions that help reduce the time and effort spent during the installation process.