This column is moderated by Béla Lipták, automation and safety consultant and editor of the Instrument and Automation Engineers’ Handbook (IAEH). If you have an automation-related question for this column, write to [email protected].

Q: We designed an addressable fire and gas (F&G) system for a cable gallery (effectively a 2-km tunnel) using SCAME (S81) technology. Thus far, detectors have been installed 1 km into the gallery, meaning we have a 2-km loop. Since there's a 3-km limit for an addressable loop, is there some other way we can extend the loop to cover the full gallery (4 km)?

Mehdi Manouchehri

[email protected]

A1: Addressable, multi-sensor detection loops can be wireless, hardwired or can use fiber-optics. Wired systems often connect on-off devices, such as smoke, fire, carbon monoxide or other sensors in HVAC applications (Figure 1). If analog measurements are to be monitored in industrial applications, fiber-optic, addressable detection loops are also often used.

The main advantage of using an addressable detection loop is cost reduction, which is obtained by lowering the installation cost when a common cable connects all devices. These loops can also detect fault events by logging them for finding and diagnosing purposes. Changes can be made with easy rewiring, including integrating sounders into the loop that connects the detectors.

As to your question, wiring distances are limited by wire size and by the allowable voltage drop between the sensors and the control panel. If one needs to increase these distances, boosters can be installed in the loops or fiber-optic designs can be considered.

Béla Lipták

[email protected]

Figure 1: To save installation costs, a variety of smart (digitally communicating) devices can communicate over a single loop.

A2: The only reliable option for long cable routes is a fiber-optic linear heat detector. This method is proven, simple and cost effective. AP Sensing and Optra are two companies that offer this solution.

Conventional, addressable smoke detectors have the following limitations:

- They can only sense fire locally and not along the whole cable route. They can measure only within a maximum, 10-meter radius.

- No addressable loop can be extended beyond 2 km and even this is only theoretical. So, this might not work and therefore the OEM’s warranty is a must.

- Outdoor locations are not suitable for smoke-detectors.

- They can give false alarms.

If you're interested in a design and proposal, please contact me.

Debasis Guha

cybersecurity specialist/digital transformation consultant

[email protected]

A3: Normally, the bus communications protocol used for the loop will dictate a maximum distance and a maximum number of devices. And for F&G applications, these parameters will depend on proprietary details of the product provider’s implementation. While I haven't used the SCAME system, other providers that I have used insert a booster into the loop to extend its range. You should review the documentation of the supplier to make sure the extended bus communication loop distance is sufficient.

Kervin Peña

[email protected]

Q: I'm studying your handbook about type J, double-ungrounded thermocouples. We have two thermocouples installed close together, and their installation, including insertion length, is the same. Normally the temperature is between 103 ºC and 109 ºC.

For some reason, between 8 and 11 a.m., one of the thermocouples reports 125 ºC and the other 115 ºC, causing a safety interlock to shut down the process. In other hours, the thermocouples work well and agree.

What would you suggest to correct this situation?

F. Alcala

[email protected]

A1: Why the problem occurs between the hours of 8 and 11 a.m., I have no idea. That has to do with something other than the thermocouples.

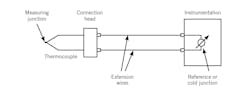

Long extension wires (Figure 2) can cause errors because of noise interference, guarding, shielding, etc. The best thing to do is not to use them. Instead, place a transmitter right on top of the thermowell. To check if the difference in the readings is caused by either of the thermocouples or the extension wires, switch the readout end of the extension wires. If this causes the problem to switch to the other thermocouple, then the cause of the error is not in the sensor or the extension wire, but elsewhere.

Thermocouples also drift because the junction of two dissimilar metals tend to degrade. If it's only a few degrees per year, this drift can be calibrated out. Long extension wires made of lesser-quality materials than the thermocouple wires themselves can also cause drift.

Béla Lipták

[email protected]

Figure 2: Thermocouples can drift due to a variety of issues, including electrical noise, grounding problems or degradation over time. The extension wires themselves can cause problems as well.

A2: Electrical feedback, noise or grounding issues can all affect thermocouple readings.

I'd recommend the following test to isolate any faults:

- Disconnect the wires of the thermocouple and connect them to a similar thermocouple, but not installed in the thermowell.

- Check if the thermocouple output is consistent with ambient temperature. If you have noise, feedback or grounding issues, then the thermocouple will act similar to the one in the thermowell.

- If the thermocouple signal holds steady with no variations, then the issue could be with the thermocouple in the well.

- Verify there's no signal feedback that can cause noise or interference with the installed thermocouple.

- Finally, remove the installed thermocouple, and bench test that there's no drifting of the signal.

By doing steps 1 and 2, you'll find out if the thermocouple cable has any issues. By doing steps 2, 3 and 4, you'll be checking for external or internal faults in the thermocouple itself. Step 5 will directly verify if the thermocouple is in good condition, or not.

Alex (Alejandro) Varga

[email protected]

A4: In the case of thermocouples and resistance temperature detectors, wiring is very critical. For the most challenging applications, you might want to consider a fiber-optic temperature sensor. GaAs temperature probes are based on the inherent relationship of bandgap energy to temperature. Because temperature is measured in the spectral domain, fiber-optic “wiring” has no effect on the measurement accuracy.

Dennis Horwitz

[email protected]